AC Induction motor vs AC Synchronous motor: Which One to Choose for Your Application?

Understanding the Differences Between AC Synchronous and AC Induction Motors for Technical Projects

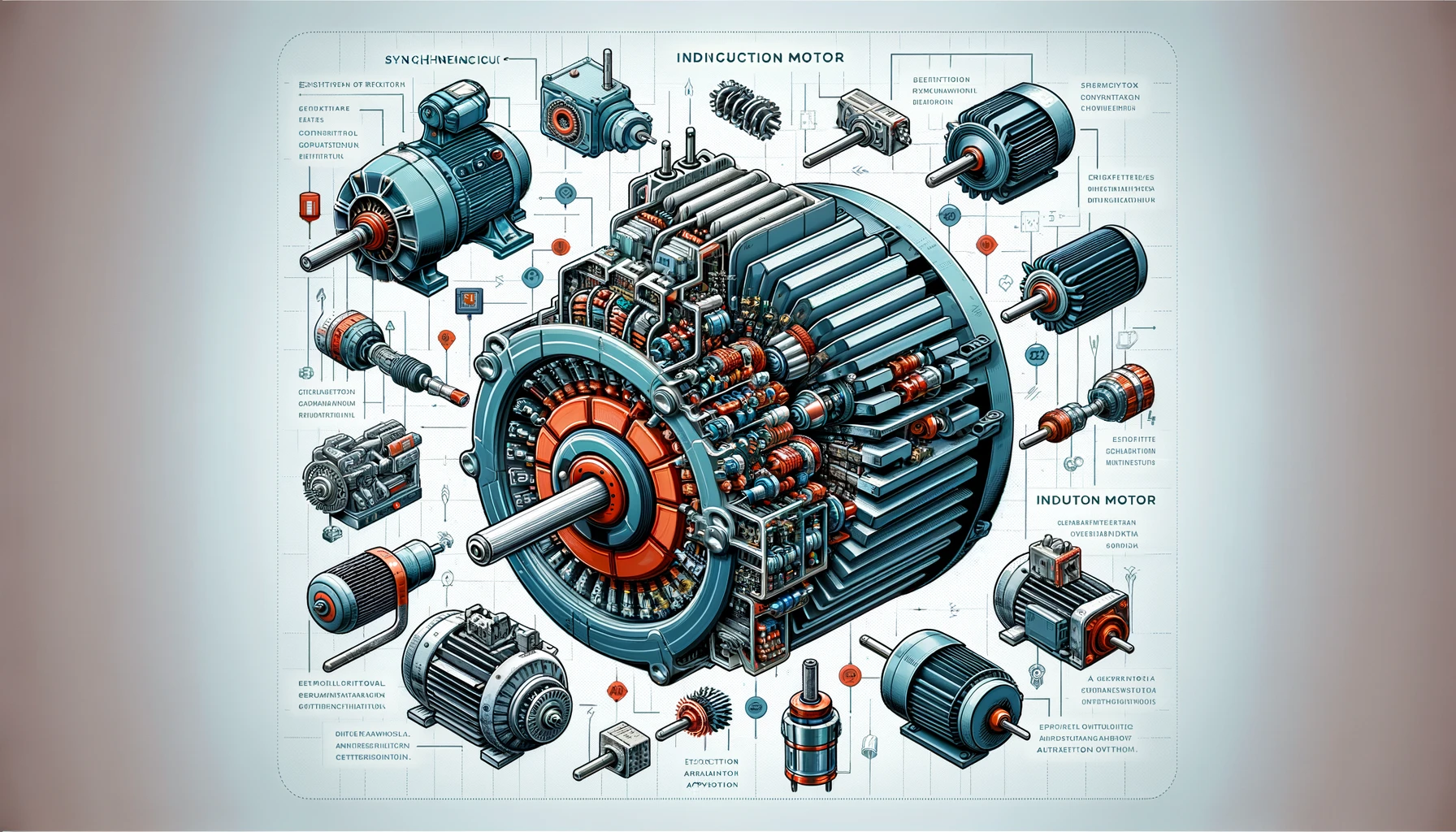

AC motors serve as a cornerstone in the realm of mechanical engineering, converting alternating current into the kinetic energy required for a multitude of devices. The primary classifications of AC motors are the Synchronous and Induction types, each with distinct mechanical functions and operational specifics.

Detailing AC Synchronous Motors

AC Synchronous Motors synchronize their rotation speed with the electrical supply’s frequency, ensuring consistent motion output. They employ a Salient Pole Rotor energized by direct current through slip rings or alternatively by permanent magnets. However, they require additional mechanisms to overcome initial inertia and begin movement.

Diving Into AC Induction Motors

Commonly referred to as asynchronous motors, these devices operate on the principle of electromagnetic induction, available in diverse configurations such as single or multiple phases. They initiate movement by producing a rotating magnetic influence in the stator that inductively prompts movement in the rotor, with the rotor’s speed dynamically adjusting to the applied load.

Motor Comparison: Synchronous Versus Induction

AC Synchronous Motors require supplemental excitation and are ideal for tasks requiring a fixed rotational speed. Conversely, AC Induction Motors are self-activating and adapt their performance to varying load demands, offering operational flexibility.

Classification of Motor Types, Features, and Adaptability

Choosing between the squirrel cage or wound rotor types in induction motors influences their response and adaptability to different operational conditions. Synchronous motors are synonymous with precision in applications demanding stringent speed regulation, in contrast to the robust and adaptable induction motors.

Considerations for Application and Industrial Use

The robust nature of induction motors makes them suitable for a broad spectrum of industrial applications, from large-scale machinery to domestic devices, while synchronous motors are typically reserved for specialized applications where exact timing is crucial.

Deciding on the Most Suitable Motor for Specific Applications

An in-depth assessment of factors such as efficiency, design complexity, and cost-effectiveness is vital to determine the most appropriate motor type for your project, ensuring efficiency and compliance with project criteria.

Comparative Analysis

Power Delivery Systems:

- Synchronous motors utilize dual excitation systems, employing AC for the armature coils and DC for the field coils.

- Induction motors rely exclusively on AC power for energizing their stator coils.

Excitation Methods:

- Synchronous machines are classified as double excited due to their separate armature and field power sources.

- Induction machines require only a single power source for excitation, simplifying their design.

Speed Dynamics:

- Synchronous machines adhere to a fixed speed, known as synchronous speed, regardless of load variations.

- The velocity of induction machines diminishes when under load, never reaching synchronous speed.

Initiation Process:

- Synchronous machines necessitate auxiliary methods for initiating rotation until they achieve synchronization at synchronous speed.

- Induction machines are equipped with inherent torque, enabling self-starting capabilities.

Functional Behavior:

- Synchronous machines can function with both leading and lagging power factors, adjustable through field excitation modifications.

- Induction machines generally work with a lagging power factor, which may deteriorate under increased load conditions.

Applications:

- Synchronous machines serve dual purposes: for reactive power management (power factor correction) and as a motive force for mechanical systems.

- Induction machines are predominantly utilized for converting electrical energy into mechanical energy.

Energy Efficiency:

- Synchronous machines typically exhibit higher efficiency than their induction counterparts for the same power output and voltage level.

- Induction machines, while efficient, tend to lag behind synchronous machines in energy efficiency at comparable outputs and voltages.

Design Complexity and Economic Factors:

- Synchronous machines are characterized by intricate designs and higher manufacturing costs.

- Induction machines, particularly those with cage rotor designs, boast simpler configurations and are more economically viable.

Deciphering these key points is essential for the informed selection of a motor, tailored to specific operational efficiency, functional demands, and budgetary constraints.

Reviews

Reviews about the product AC Induction motor vs AC Synchronous motor: Which One to Choose for Your Application?